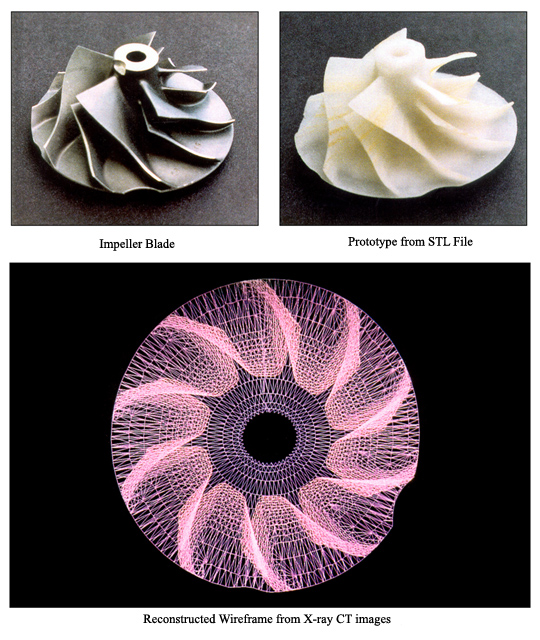

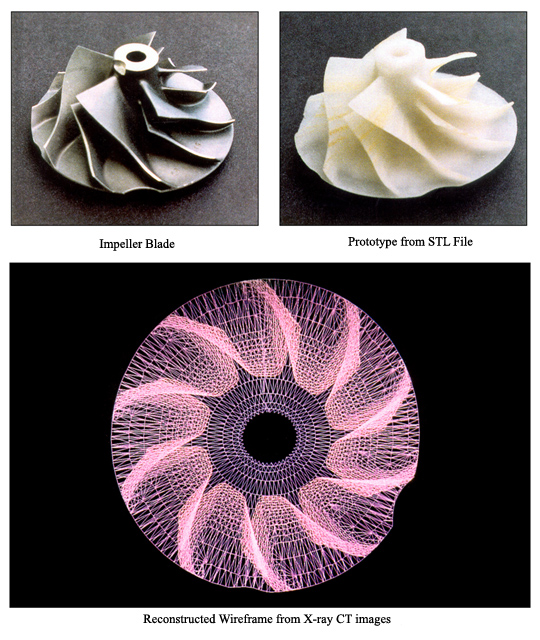

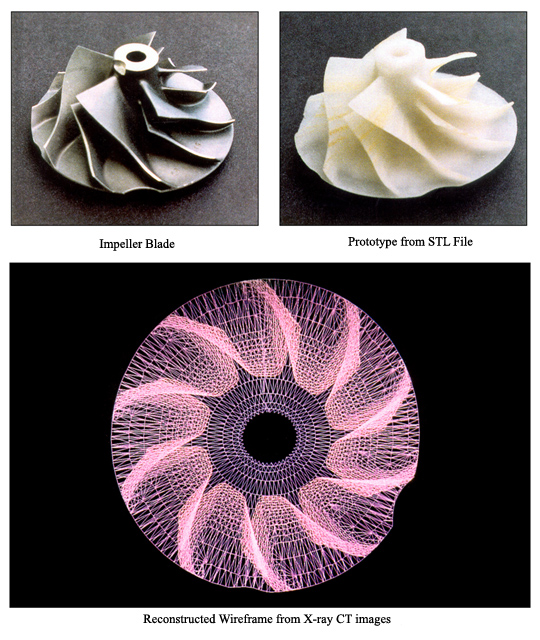

The images below are of a turbo impeller blade. The top left image is of the actual

impeller blade. The large bottom image is a computer generated wire frame

model from CT slices for use in CAD/CAM. The top right image is

the 3D output from a laser-sintering machine (material polycarbonate). Often

companies from the Auto and AeroSpace industry would ask SMS

(company I worked for at the time) to do a 3D scan of a competitorís part. This

was for the purpose of finding out how it was made and to possibly modify

the part for use as their own. This process is known

as "

Reverse Engineering". I made

over 20 different models using this process while at SMS. The models

used a varity of different materals like nylon, wax, paper, plastic, photopolymers, and polycarbonate.

Click on picture to view a bigger image.